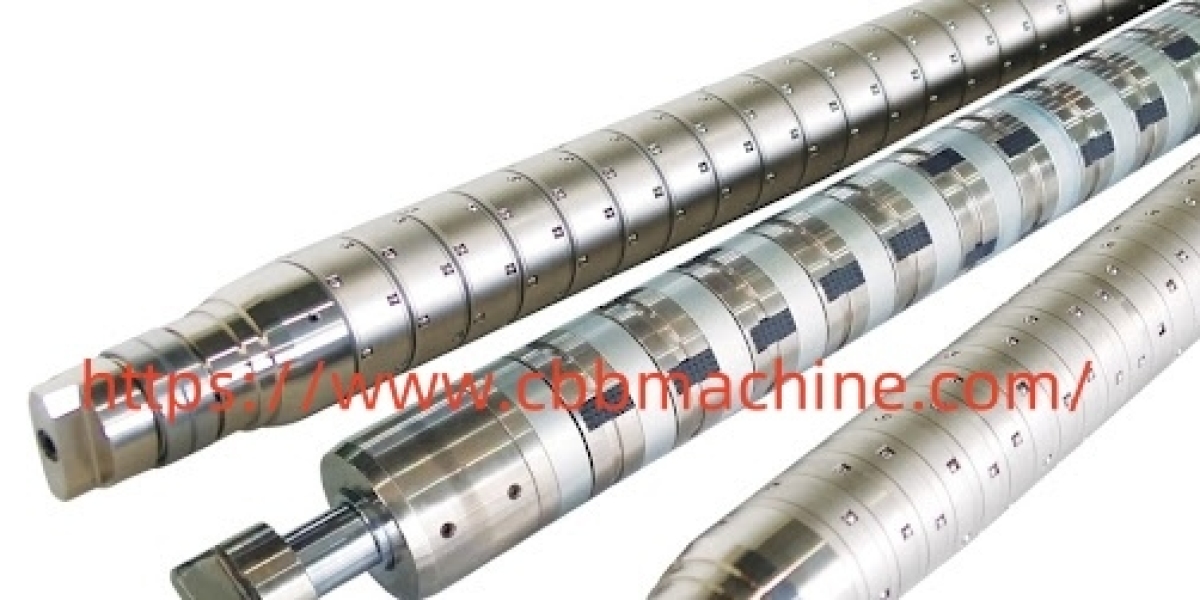

In modern industrial production, managing the tension of flexible materials is essential for maintaining product quality and minimizing waste. A Differential Air Shaft provides an effective solution for this challenge by distributing air pressure evenly across rolls during winding and unwinding processes. This precise control ensures that materials like films, papers, or textiles are processed without stretching, wrinkling, or misalignment, which can otherwise compromise final product integrity.

The operation of these shafts relies on air pressure to adjust tension automatically, offering a significant advantage over purely mechanical systems. Unlike traditional shafts that may require manual adjustments or complex gearing, air-based systems provide smooth, responsive control. This reduces mechanical wear, decreases maintenance needs, and enhances overall operational efficiency. Manufacturers can rely on this technology to keep production lines running consistently, even when switching between materials with different thicknesses or mechanical properties.

One of the key benefits of integrating such a shaft is the versatility it brings to production processes. Industries that handle diverse product lines benefit from the ability to adapt quickly to material changes without significant downtime. Operators can easily regulate air pressure, ensuring uniform tension across the entire roll width. This adaptability not only improves product quality but also contributes to reduced material wastage, which is an important consideration in large-scale production environments.

Safety is another significant factor. The air-based tension control minimizes the need for heavy mechanical brakes or clutches, reducing the risk of accidents and protecting both operators and equipment. Additionally, precise tension management prevents sudden shifts or roll slippage, which can damage machinery or products. With increasing automation and high-speed production demands, this technology becomes critical for maintaining reliable and safe workflows.

As manufacturing continues to evolve, future developments in these shafts may include enhanced sensor integration, automated adjustments based on real-time material feedback, and compatibility with new materials. Such innovations will allow industries to meet growing demands for higher efficiency, consistent quality, and reduced operational costs. Investing in advanced tension control solutions ensures that production remains competitive and resilient in the face of modern manufacturing challenges.

For more information, visit https://www.cbbmachine.com/news/industry-news/differential-air-shafts-key-components-applications-benefits-and-more.html